The MYCRONIC MY700 Jet Printer is changing the game in PCB manufacturing. It's making high-precision solder paste application in SMT processes easier. This advanced system brings many benefits that are improving PCB assembly efficiency and quality.

The MYCRONIC MY700's success comes from its cutting-edge technology. It controls the amount of solder paste applied to the PCB with great precision. This ensures consistent, high-quality solder joints. As a result, the final electronic assemblies are more reliable and perform better.

Key Takeaways

- Precise solder paste deposition for reliable PCB assembly

- Improved manufacturing efficiency and productivity

- Enhanced quality control and inspection capabilities

- Cost-effective production solutions

- Flexibility in handling diverse manufacturing requirements

Understanding the MYCRONIC MY700 Jet Printer Technology

The MYCRONIC MY700 Jet Printer is a top-notch industrial inkjet printer. It's designed to change the game in PCB manufacturing. It has a smart design, with advanced printing tech and easy software use.

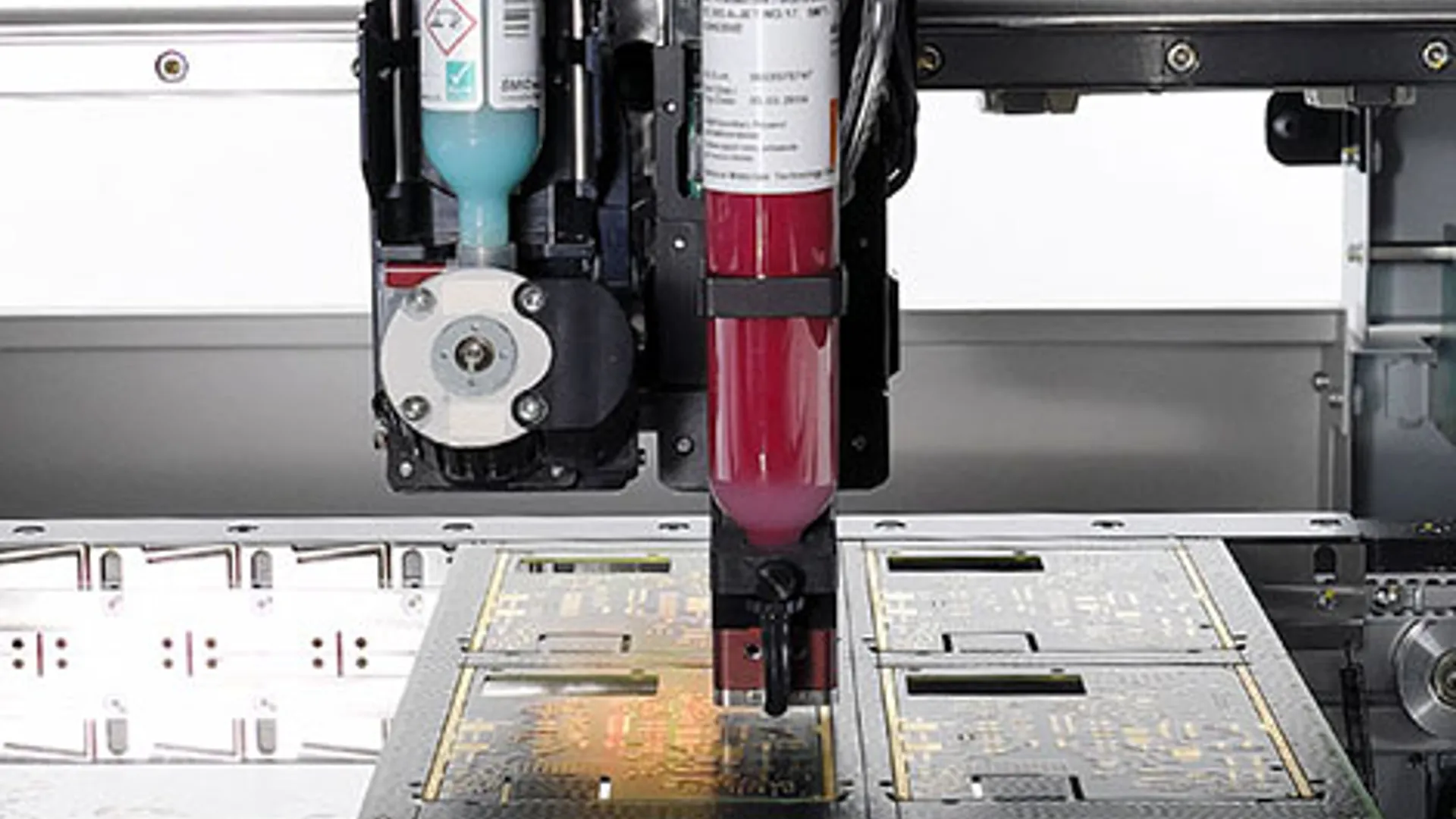

Core Components and Architecture

The MYCRONIC MY700 Jet Printer is built to last. It has a modular design for easy changes and growth. It includes precise print heads, smart fluid management, and exact motion control for top printing quality.

Advanced Printing Mechanisms

The MYCRONIC MY700 uses advanced piezo-electric print heads. These heads ensure precise solder paste application for great PCB assembly results. Its drop-on-demand tech and smart nozzle control also cut down on waste and boost efficiency.

Software Integration Features

The MYCRONIC MY700 works seamlessly with top software. Its advanced software offers tools for easy setup, live monitoring, and quality checks. This makes the PCB manufacturing process smoother.

The MYCRONIC MY700 Jet Printer stands out with its strong design, leading-edge printing tech, and smart software. It sets a new benchmark in industrial inkjet printers and mycronic my700 specifications.

High-Precision Solder Paste Application in PCB Manufacturing

The MYCRONIC MY700 Jet Printer is changing the game in precision printing. It offers unmatched accuracy in applying solder paste for semiconductor equipment. This new tech is transforming PCB production, ensuring top-notch quality and reliability.

The MY700's secret is its advanced solder paste deposition system. It uses cutting-edge jetting tech to apply solder paste with incredible precision. This means it can place solder paste within ±25 microns, which is vital in PCB making.

| Feature | Benefit |

|---|---|

| Exceptional Placement Accuracy | Ensures consistent and reliable solder paste application, reducing defects and improving product quality |

| Advanced Jetting Technology | Enables precise control over solder paste deposition, allowing for optimal deposit size and placement |

| Uniform Solder Paste Distribution | Enhances the overall quality and consistency of solder joints, contributing to improved product reliability |

Using the MYCRONIC MY700's precision printing, makers can boost their production and quality. This leads to better semiconductor equipment for customers. The MY700's precision and advanced software make it a key tool in precision printing and semiconductor manufacturing equipment.

Revolutionary Speed and Throughput Capabilities

The MYCRONIC MY700 Jet Printer is changing the game in high-speed printing and flexible manufacturing. It brings new levels of productivity and efficiency to PCB assembly.

Maximum Production Rates

The MY700 Jet Printer uses advanced print head technology and smart software. It can print up to 2,200 boards per hour. This makes it a top choice for high-volume manufacturing.

Cycle Time Optimization

Maximizing throughput is key in PCB assembly. The MY700 Jet Printer is designed to optimize cycle times. It has features like fast board loading and unloading, and seamless software integration.

Multi-Board Processing

| Feature | Benefit |

|---|---|

| Simultaneous multi-board processing | Increased production capacity and throughput |

| Automated board handling and transportation | Reduced manual intervention and improved efficiency |

| Advanced nesting algorithms | Maximized utilization of available print area |

The MY700 Jet Printer's multi-board processing capabilities boost its throughput. This lets manufacturers produce more and stay competitive in high-speed printing and flexible manufacturing.

The MYCRONIC MY700 Jet Printer brings many benefits to PCB manufacturing. It has advanced printing and software integration. This technology is changing the industry.

The MYCRONIC MY700 is known for its high-precision solder paste application. This ensures consistent and reliable results. It also reduces defects and improves PCB assembly quality.

- Exceptional printing accuracy for intricate PCB designs

- Consistent solder paste volume and placement across the board

- Reduced waste and rework, leading to cost savings

The MYCRONIC MY700 also has revolutionary speed and throughput capabilities. It helps manufacturers work more efficiently. Its advanced engineering and software integration optimize cycle times and allow for processing multiple boards at once.

- Impressive production rates for high-volume PCB assembly

- Streamlined cycle time optimization for improved productivity

- Multi-board processing capabilities for enhanced throughput

The MYCRONIC MY700 also offers enhanced quality control and inspection features. It has automated inspection systems and error detection. This ensures consistent quality and reduces the risk of defects.

The MYCRONIC MY700 Jet Printer is a game-changer in the PCB industry. It offers cost-effective production and flexibility in manufacturing. Its ability to adapt to various products and quick changeover capabilities make it invaluable for modern manufacturing.

Enhanced Quality Control and Inspection Features

The MYCRONIC MY700 Jet Printer has top-notch quality control and inspection features. It ensures high-quality precision printing for semiconductor manufacturing equipment. These features go beyond standard PCB production, offering unmatched quality assurance and process optimization.

Automated Inspection Systems

The MYCRONIC MY700 uses advanced automated inspection systems. These systems carefully check each printed circuit board. They use smart algorithms to spot even the smallest defects, making sure only perfect boards move forward.

Error Detection and Correction

The MYCRONIC MY700 Jet Printer has built-in error detection and correction. It finds and fixes problems during printing. This smart system makes adjustments on the fly, reducing errors and boosting production efficiency.

Quality Assurance Protocols

The MYCRONIC MY700's quality control is backed by strict quality assurance protocols. These detailed procedures cover every step of the printing process. They ensure each printed circuit board meets the highest standards for precision printing in semiconductor manufacturing.

| Feature | Benefit |

|---|---|

| Automated Inspection Systems | Precise detection of even the smallest defects, ensuring flawless PCBs |

| Error Detection and Correction | Real-time adjustments to maintain optimal printing parameters and efficiency |

| Quality Assurance Protocols | Comprehensive quality control procedures throughout the entire printing process |

Cost-Effective Production Solutions

In the fast-paced world of industrial manufacturing, saving money is key. The MYCRONIC MY700 Jet Printer is a top-notch flexible manufacturing tool. It helps cut costs in the production process, making it a smart choice for PCB makers.

The MYCRONIC MY700 makes production smoother. It uses advanced tech for precise solder paste and fast printing. This means less waste, less downtime, and lower labor costs. It helps businesses stay ahead in a changing market.

This printer is also super versatile. It changes products quickly and handles many products at once. It's easy to program, adapting to new needs and trends. This flexibility helps manufacturers keep costs down and profits up.

The MYCRONIC MY700 Jet Printer is a smart pick for cost-aware PCB makers. It boosts production, cuts waste, and fits changing market needs. It's a key tool for growing sustainably and profitably.

Flexibility in Manufacturing Operations

The MYCRONIC MY700 Jet Printer brings unmatched flexibility to manufacturing. It allows for fast changes in products, handling multiple items at once, and easy programming. This helps businesses keep up with changing market needs and stay ahead.

Quick Product Changeover

The MYCRONIC MY700 Jet Printer makes quick changes easy. Its user-friendly interface and automated setup mean less downtime. This lets manufacturers quickly switch to new products, keeping production running smoothly.

Multi-Product Capability

Manufacturers can work on many products with the MYCRONIC MY700 Jet Printer. Its flexible manufacturing lets different parts work together. This makes producing small to medium batches of various products cost-effective.

Programming Versatility

The MYCRONIC MY700 Jet Printer's software is highly customizable. It lets manufacturers tweak production settings, improve surface mount technology, and make adjustments on the fly. This boosts overall efficiency.

Using the MYCRONIC MY700 Jet Printer's flexibility, manufacturers can quickly adapt to market shifts. This boosts their competitiveness and supports sustainable growth in today's fast-changing world.

Environmental Impact and Sustainability Benefits

The MYCRONIC MY700 Jet Printer is made with the environment in mind. It uses efficient industrial inkjet technology. This printer cuts down on material waste, making PCB production more eco-friendly.

The MYCRONIC MY700 controls solder paste application well. This means less material is used and less waste is thrown away. It also makes the final product better and reduces environmental harm from excess solder paste and cleaning.

This printer is also small and uses less energy. It helps semiconductor makers be more green. It fits with the industry's push for being eco-friendly and responsible.

FAQ

What are the key advantages of using the MYCRONIC MY700 Jet Printer in printed circuit board (PCB) manufacturing?

The MYCRONIC MY700 Jet Printer has many benefits for PCB manufacturing. It applies solder paste with high precision. It also prints fast and efficiently, improving quality and reducing costs. Plus, it makes manufacturing more flexible.

How does the MYCRONIC MY700 Jet Printer achieve high-precision solder paste application?

The printer uses advanced technology to apply solder paste accurately. This leads to better quality and reliability in PCB assembly.

What are the revolutionary speed and throughput capabilities of the MYCRONIC MY700 Jet Printer?

The printer is incredibly fast, with high production rates and optimized cycle times. It can handle multiple boards at once, boosting productivity.

How does the MYCRONIC MY700 Jet Printer enhance quality control and inspection in the manufacturing process?

The printer has automated systems for checking quality. It can detect and fix errors, ensuring high-quality PCBs every time.

How does the MYCRONIC MY700 Jet Printer contribute to cost-effective production solutions?

Its advanced features and efficient operation lower production costs. This makes PCB manufacturing more profitable.

What flexibility does the MYCRONIC MY700 Jet Printer offer in manufacturing operations?

The printer is easy to switch between products. It can handle multiple products and is easy to program. This makes it adaptable to changing needs.

What environmental impact and sustainability benefits does the MYCRONIC MY700 Jet Printer offer?

The printer is designed to be efficient and waste-reducing. This makes PCB manufacturing more sustainable, with less environmental impact.